Roll coating machines are commonly used for the industrial application of a liquid to the surface of a part. Rollcoaters can be used to apply liquid adhesives, paints, oils, and coatings such as varnish or clear finish coats. Rollcoaters can take many forms, from simple paint rollers to sophisticated coating machines with multiple rollers. A roll coating machine works by transferring a layer of coating from the surface of a roller to the surface of a part. When this happens, a phenomenon know as “film splitting” occurs. The layer of coating on the surface of the roll splits – part of it stays on the roller, and part sticks to the surface of the part. The percentage of coating that sticks to the part (the substrate) depends on the surface characteristics of both the roller and the substrate.

With most rollcoaters, there is some means of controlling the thickness of the coating on the surface of the roller before it contacts the substrate. The three most common approaches to controlling the coating thickness are metering blade, metering roller, and transfer from another roll.

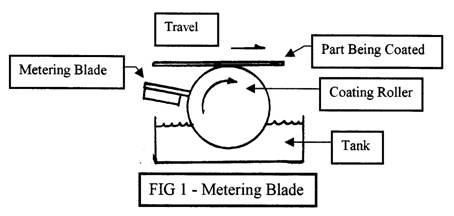

A typical arrangement for a metering blade is shown in Figure #1. Coating is picked up from a reservoir by the application roller. As the coating clings to the roller and is carried up by the rotation of the roller, only a certain amount can pass through the gap between the metering blade and the roll surface. The excess flows back to the tank. Metering blades are usually made with some means of adjustment, so coating thickness changes are made by moving the blade to open or close the gap.

In some cases the metering blade may be moved forward and back on its mount plate, It can also be rotated to change the gap between the metering blade and the roller. The advantages of a metering blade over other means of coating thickness control are low cost, simplicity of design, and the fact that the metering blade system does not require much space. Two disadvantages are the potential for clogging and potential for roller damage. Clogging can occur if debris or foreign matter in the liquid gets caught in the gap between the coating roller and the metering blade. This can block a portion of the coating from passing through the gap, which can cause streaks or inconsistent coating results. In cases where the debris is abrasive, it can cause damage to the surface of the roller.

Some types of coatings also tend to congeal or clump if subjected to situations where there are shear forces on the liquid. This situation occurs between a metering blade and a coating roller. For this reason materials such as latex adhesives do not run well in machines having metering blades. This type of adhesive would form clumps which would clog the metering blade to roller interface.

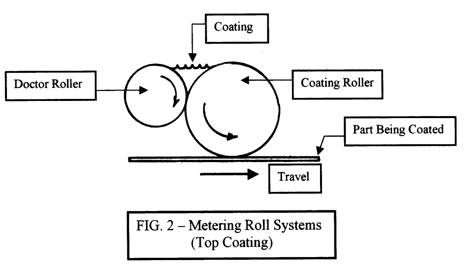

Typical metering roll arrangements are shown in figure #2. In a metering roll system, the thickness of the coating is controlled by adjusting the gap between two rollers. In a typical bottom coating application the coating is picked up from a reservoir and carried up to a nip point by one roll, then the excess is metered off by a second roll which also serves as an application roller. A similar concept is used when coating must be applied to the top surface of a part. Coating is held in the valley formed between the metering roller and coating roller, and the gap between the rollers is adjusted to change the coating thickness.

Metering roller systems are more expensive to build than metering blade systems, but have several advantages. They are more tolerant of debris or foreign matter in the liquid, since it can often pass through the gap between the rolls and go back into circulation. If the coating roll and metering roll are run at similar surface speeds, shear sensitive materials such as latex can be applied without problems. In some situations, the coating roll and pickup roll are run at different surface speeds. This can be done to minimize the formation of foam in the tank, or to help smooth out the layer of coating on the coating roller.

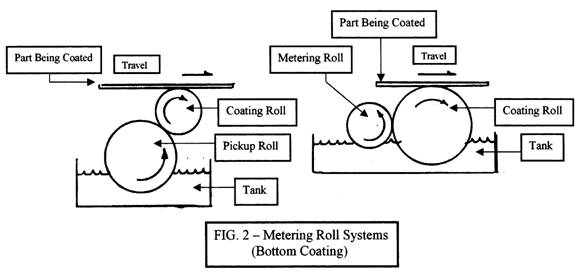

In reverse roll coating, the surface of the part is fed across the coating roller in the opposite direction to the surface travel of the coating roller. This causes the coating roll to serve both as an application roller and a wiper roller. A small puddle of coating can form at the interface of roller and substrate, and this flows onto the part as it passes under the coating roll. A reverse roll coating arrangement is shown in Fig 3.

Reverse roll coating is used to apply heavier coatings than might be possible with forward roll coating. It is also possible to apply a very smooth coating by using the reverse roll technique. Since the coating is heavier, it tends to flow out better, and the flow from the puddle at the roller to part interface tends to smooth out the coating. The result of these two effects working together can provide coatings that are very flat and smooth.

The difficulties in reverse roll coating are in driving the part and in dealing with any coating build-up on the leading or trailing edges of the part. In order to travel in the opposite direction from the coating roller, the part must be driven in a positive manner so that it does not slip. This can be done with pressure rolls having high friction coverings, with vacuum conveyer systems, or with drive belts having cogs or raised bosses to push the parts through.

If a very heavy coating is being applied, it can drip over the lead edge or trailing edge of the part. With some types of parts this does not pose a problem, but with others it can cause coating to transfer to the pressure rolls or feed conveyer and require cleanup. This problem can usually be controlled by finding the optimum settings for coating weight, roller speed, and the speed of part travel.

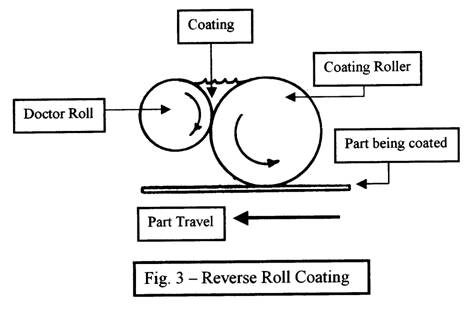

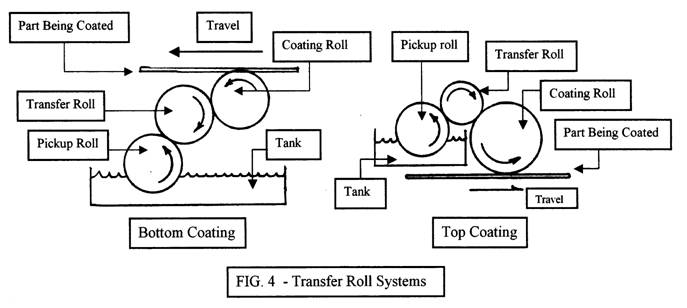

Transfer roll systems (Fig 4) are actually a variation of the metering roll system, and utilize additional rollers to transfer the coating from the reservoir to the final point of application. Because additional rollers are involved, these systems are more expensive than designs using only a metering roller and application roller, but there are several reasons why transfer rollers are used in some types of equipment. These reasons are coating thickness, roller space limitations, and special roller surface material requirements.

In general transfer roll systems are capable of depositing a thinner coating than two roll systems. This is because a film split occurs at every roller interface, so the film of coating will be thinner on each consecutive roller in the roller train.

Roller space limitations also may dictate the use of transfer rolls. In some types of equipment, there is not enough space to place large diameter metering rollers close to the application point, and transfer rolls can be used to carry the coating from the initial metering point to the application point.

Transfer rolls can also be used in situations where the application roller must be made of a material that is not well suited to use as a metering roll (such as a soft rubber). In these cases, metering of the coating is done with metal rolls or hard surfaced rolls, and the coating is transferred to the application roll. This configuration can also be useful in situations where rolls are used to transfer a pattern, such as certain types of printing presses. The coating is metered out to the surface of one roller, and the application roll picks up the coating on a printing plate wrapped around the application roll. The plate transfers the coating to the part.

Besides cost, one disadvantage of transfer roll systems is that they are more difficult to adjust and calibrate than metering blade or two roll metering systems. In some situations additional rolls or wiper blades must be added to prevent an accumulation of coating on rolls when parts are not being coated.

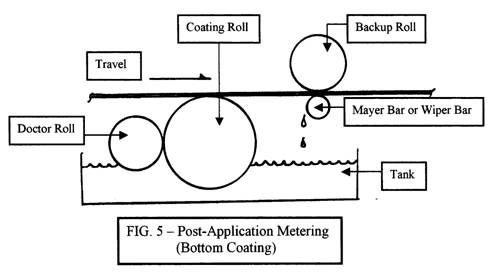

In many applications roll coating machines are used to apply an adhesive or finish coating to a part, but the thickness or finish of the layer being applied does not meet the requirements of the end product. In these cases a secondary metering method can be used after the coating is applied to either thin out the coating, smooth it, or texture it to meet the final requirements.

Almost all post application-metering situations are used when the material being coated is in the form of a continuous web. One method that is very popular is the use of a mayer rod or mayer bar. This is a rod wound with a layer of round wire. This device can be used to both meter and smooth out a layer of coating. The bar is used as a scraper bar to wipe off excess coating, and the spaces that exist between the round wires serve to meter out a uniform layer of coating. In most cases the material being metered off will form a series of peaks and valleys that will flow out to form a smooth uniform layer. Mayer bars may be used in sequence to do rough metering then fine metering/smoothing, and are used on many production lines that produce pressure sensitive films, tapes, and other materials that require a thin, smooth finish coating. A configuration using a mayer rod is shown in FIG 5.

In certain cases, application rolls can be built with surface textures that provide the type of surface finish desired without post-application metering. The ability to do this will often depend on the characteristics of the coating being applied, as well as the characteristics of the substrate. With the right combination of characteristics, a simple machine may be able to produce results that normally would be produced by a more complex machine. Some machines are built with application rollers having grooves, knurled surfaces, or engraved surfaces designed to carry more coating than can be carried by a smooth roller. The surface texture can be used as a method of controlling the amount of coating deposited by a roller.

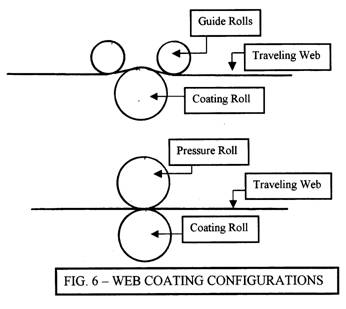

The majority of coating applications are ones where a continuous strip (web) of material is coated, then dried (or chilled), and rewound into a roll. Web coating lends itself to high production rates, and can be used with almost all types of adhesives and coatings. Many web coating applications utilize roll coaters to apply the adhesive or coating, and most utilize some form of post-application metering. In general, web coating is done at much higher speeds than sheet coating, and considerable attention must be given to factors such as proper web tracking, web tension control, web flutter, and stretching. Since the web is a continuous strip, it can pass over a number of rollers as it is being coated or treated, and some web coating configurations can be very complex. An engraved roller (gravure roll) is used in many web-coating applications. This is used to transfer a very precise amount of adhesive to the web. Two typical web coating configurations are shown in Fig 6, both of them utilizing a gravure roller.

With any roll coater, the substrate to be coated must be brought into contact with the application roller to pick up coating. In some situations the part can be directly pressed against the coating roller by a pressure roll, and in others the substrate must be guided over the surface of the coating roller so that it just kisses the roller with enough contact to pick up the liquid. Pressure rolls are sometimes called feedrolls, backup rolls, or guide rolls.

The configuration of the pressure roll relative to the coating application roll is usually determined by the thickness and flexibility of the substrate to be coated. If the pressure roll is too close to the coating roller there is a possibility that it can pick up excess coating that flows off of the substrate, and then transfer this coating on the opposite side of the substrate. In some cases a droplet of coating can travel around on the surface of the pressure roll. This can allow it to pick up a bit of coating on each revolution until the roll becomes almost totally covered, requiring that the equipment be stopped for cleanup.

When coating thin substrates the pressure rolls must be a sufficient distance from the coating roller to avoid contamination, but still ensure that the substrate can be driven through the machine and pick up a coating. This can be accomplished by locating the pressure rolls in such a way that the substrate is forced to bend over the coating roller, or by pressing the part directly against the coating roller with the pressure roll and removing any excess that transfers to the pressure roll with a wiper or cleaning roll. A third technique is to coat only a portion of the substrate and leave the edges uncoated to avoid any transfer of coating.

If the substrate to be coated is sufficiently thick there is less chance of coating transfer and the pressure roll can be located so that it presses the part directly against the coating roller.

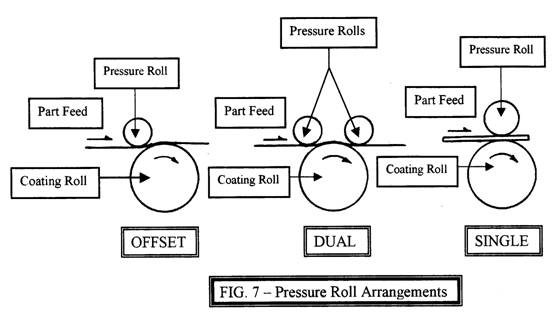

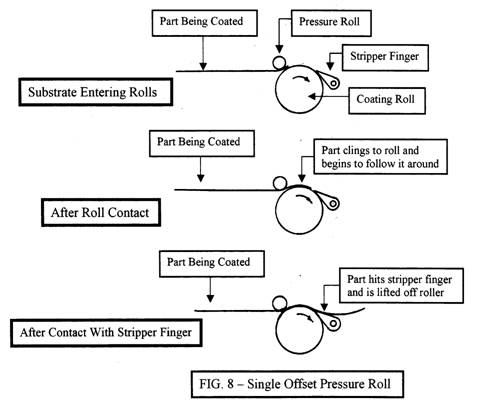

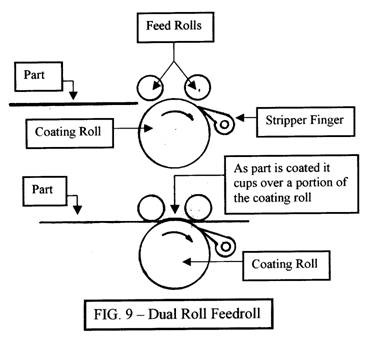

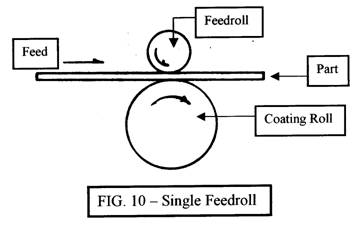

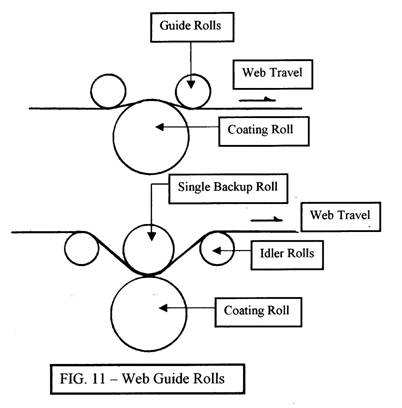

Different configurations of pressure rolls relative to coating rolls have been used for various types of equipment. Some typical configurations are shown here:

In the configuration shown in Fig 8 the substrate must flex as it hits the coating roll, and the deflection creates a slight pressure of the substrate to the roll. Once the substrate is in contact with the roll, the surface tension of the adhesive will tend to cause it to stick to the roll and be pulled through the machine. The stripper points indicated are small knife like fingers designed to break the leading edge of a flexible substrate free of the coating roller and allow the part to feed through without wrapping around the coating roller. This type of single pressure roll configuration is typically used with paper.

With the roll configuration shown in Fig 9 the two pressure rolls force the part to cup over the coating roller and pick up a full coating. The part flexes upward as it passes under the first roller and hits the coating application roll, and is forced around the coating roller as it hits the second pressure roll.

This roller arrangement can be versatile – it can often be used with a range of substrate thicknesses, since moving the pressure rolls relative to the coating roller can allow paper to be coated when the rolls are close to the coating roll, and thicker parts coated as the pressure rolls are moved away from the coating roll. By raising the dual rollers high enough above the coating roller, it may be possible to also coat rigid and semi-rigid substrates with this roll configuration. Stripper fingers are generally used with flexible substrates, but may not be required with stiffer materials.

In Figure 10 the part is pressed directly against the coating roll by the pressure roll. If the part has sufficient thickness, stripper fingers are not needed since the part will not cling to the coating roll. Pressure rolls may or may not be driven, depending on the type of material being coated and the type of adhesive, since some types of adhesive generate sufficient driving force to pull the part through the machine.

The configuration shown in Fig 11 is designed to force a traveling strip of material to come in contact with the coating roller and pick up coating. Web guide rolls do not need to be driven, since the web is generally pulled by a rewind or take-up roll, and the tension on the web creates the pressure of the substrate against the coating roller.

In web coating, it is possible to pull the substrate over the coating roller at a different speed than the surface of the roller. This technique is often used to deposit a thinner layer of coating than would be deposited by the roller running at the same speed as the web. The traveling action of the web can also cause the coating roller to act as a wiper bar, so that the coating is smoothed out as it gets squeezed between the web and the coating roller.

The selection of the best roll coating machine for any particular type of work depends on a number of factors. The key questions that need to be considered are as follows:

The type of adhesive or coating will influence the way the liquids are brought to the metering point. Although most adhesives will work for short periods of time in any type of rollcoater, problems can occur with certain adhesives that would cause the coating results to become inconsistent as the material runs for longer periods. Some general guidelines are as follows:

1) Evaporation of the solvent or water in an adhesive is a major consideration in how well it will run in a roll coater. When running solvent based materials, as little surface area as possible should be exposed, and material should be in constant agitation to prevent dead areas which can form a skin of partially dried adhesive. Machines designed for solvent base adhesives or fast setting water based adhesives would have rollers shielded as much as possible, and would include pumps or other methods to keep the material in constant circulation.

2) Machines for latex-based adhesives would be designed to minimize areas where the adhesive would be subject to a shearing action which could cause clumps to form.

3) It should be easy to add fresh adhesive to any machine. The design of the tank should be a compromise between the capacity and the exposed surface area. Too large a tank may cause too much surface area to be exposed to evaporation, but too small a tank may require constant refilling. Automatic refill systems can be fitted to some machines to alleviate the need to refill constantly.

4) Some types of materials do not flow well, and need to be pumped to the metering point. In some cases these materials can be carried up by a pickup roll that rotates slowly enough to be wetted by the adhesive, but in other cases pumping systems are required. This is especially true with certain high viscosity materials such as epoxies, solvent cements and urethane adhesives.

5) Certain types of adhesives and coatings have special characteristics that must be taken into account when selecting or designing a rollcoater to handle them. An example of this are Ultraviolet cured coatings (UV cure). Machines that are used to apply these coatings must have shielding or guarding in place to keep the coating shielded from light as much as possible, since light exposure can cause UV cure coatings to catalyze earlier than desired or can degrade the characteristics of the coating.

The type of adhesive will affect the choice of materials for the rollers and reservoir, the approach to coating thickness control, the method of machine cleanup, and the way that coating gets delivered to the metering point. Certain types of adhesives (such as hotmelts, waxes and certain high viscosity materials) require that the machine or the rollers be heated to melt the material or lower the viscosity to a point where it can be applied. Some adhesives or coatings will react with certain metals or other materials, and this can degrade the adhesive as the machine runs, or cause damage to the coater. Examples of this are the reactions of copper containing alloys with latex cements and U.V. cured adhesives. Other examples of incompatible materials would be aluminum components used with highly acidic adhesives (such as hot animal glue). In this case the metal components would be attacked and damaged by the glue.

Some adhesives are sensitive to a shearing action which occurs with a scraper blade, and can tend to congeal when subjected to this type of force. These adhesives and coatings must be run in machines having metering rollers.For adhesives and coatings that must be heated either the rollers must be heated directly or the tank which holds the material must be heated, and the heat from the tank and material transferred to the application roller. The need for heating can limit the choice of materials for the roller, since any material selected must be capable of maintaining critical dimensions when heated to the operating temperature.

With any type of coating machine the type of adhesive or coating will affect the cleanup method. Some types of materials can be easily cleaned – others require extensive washing with solvents or water to remove any residue. Most machines used for the application of hotmelts do not require cleanup. The adhesive is simply allowed to cool and hardens up in the machine. One exception to this are the “reactive” hotmelts or “moisture cure” hotmelts which must be purged from the equipment before it is shut down.

The thickness of the substrate determines the type of feed roll configuration that will give the best results in coating the part. The part must be able to come into full contact with the coating roller to pick up a consistent coating, but should not cause the coating to transfer to the feed roller (or feed rolls).

Thin flexible substrates (such as paper), are usually best coated by using an offset pressure roller or dual feed roller arrangement, and coating of individual sheets will require the use of stripper fingers. Extremely flexible substrates such as fabrics, thin foam, non-woven fabric, thin rubber etc, can be very difficult to coat since they will tend to bunch up and fold over themselves as they exit the coating point. In some cases, these types of material can only be coated using a backing board of sufficient stiffness, coating them in a web form, or by leaving a portion at the leading edge uncoated, and using this part to pull the substrate through the coating point. This can be done by loading the part into the coating machine with the feed roller open, then bringing the feed roller into a position where it can drive the part while there is some tension on the part to keep it from going slack and bunching up.

Thicker or stiffer substrates can be driven with a dual feedroll or single feedroll arrangement. In some cases, stiff substrates such as plywood or fiberboard can present problems, since they may have high and low spots that will bridge over the coating roll and create voids in the coating. For these types of materials a soft faced coating roller may be needed to contact the entire surface and apply coating.

In general, the width of a roll coating machine should be at least 2 inches wider than the widest part to be coated. With this extra width, if the part is loaded into the machine slightly crooked, the full surface will still get coated.

Roll coating machines are available that can apply coating to only a portion of a sheet or the full surface. There are also pattern coaters available that can apply stripes or other types of patterns in the same manner as a printing press (see transfer roll systems). In selecting a coating machine, it is important to define the area to be coated. Is it full surface, a pattern, or a stripe along one edge?

Once a part is coated with adhesive, it can become much more difficult to handle than a dry part, so it is important to think about how the part will be handled once it is coated.

The simplest and least inexpensive roll coaters coat the bottom surface of the part. This means that the part must be handled immediately as it exits the machine, and must be handled by the coated surface. With many types of parts this does not present a problem, but potential problems with wet glue getting on operators fingers need to be addressed. If the operators are able to handle and locate parts without contaminating the clean surfaces there will be no problem, but in some cases the operators will need to use special tools to handle the parts, or wipe their fingers clean of glue at some point in the gluing and assembly operation.

With machines designed to apply adhesive or coatings to the top surface of the parts the issue of glue contamination is drastically reduced. The top surface of the part is coated, and the bottom side remains clean for handling. Parts can be fed directly onto a conveyer- (which is not possible with bottom-coated parts). This can be important with large parts which would be awkward to handle by the coated surface. Top Coating is essential for parts which are being coated with a finish coat, since the finish coat must have time to self-level and flow out into a smooth coating after being applied.

With any rollcoater, any adhesive remaining in the machine after operation is complete must be cleaned completely or it can dry on the rollers or other parts of the machine and cause problems. Liquids which do not dry (such as oils) can be left in the machine, as can most hotmelt adhesives, but other types of adhesive and coatings must be cleaned out of the machine.

Ease of cleanup must be considered when selecting a rollcoater. Most rollcoaters are designed for quick cleanup, and may incorporate features in their design to facilitate this aspect of operation. Some design features that are used to make cleanup easier are:

a) Washdown systems for rollers and tanks

b) Removable coating units

c) Easily removable tanks

d) Separate wash tanks

e) Built-in flush systems (often used on printing equipment)

f) Removable rollers

Once the factors described above are taken into consideration, the choice of a rollcoater suitable for the work to be done will often be narrowed down to one or two machines. As each question is answered, only one or two machines from any manufacturer may fit the requirements, so by the time the entire list of questions is reviewed, the choice of the best machine for the job will usually be obvious. In some cases questions about the suitability of a roll-coating machine for a particular application still remains. In these cases the best way to answer the questions is to run a test using the rollcoater, the adhesive, and the substrate together to determine if they produce the desired results.